Committed to research and develop the world's leading safety relief solutions

Leader in safety and pressure relief technology, with domestic and international leading patents and technologies

This is used for power plant boiles, pressure containers, pressure and temperature reducing device and other facilies.

Note:Types and Specifications of Safety devices need to be calculated and selected according to the specific working conditions of the protected equipments and systems before quotations.

We offer 24/7 Emergency support. Contact our instant access emergency line for immediate problem resolution.

Tel: +86 516 8577 6002

WhatsApp: +86 13912009262

International Inquiries | E-mail: sales@basco.cc

Use

This is used for power plant boiles, pressure containers, pressure and temperature reducing device and other facilies. It serves to ensure the safety of the device during working.

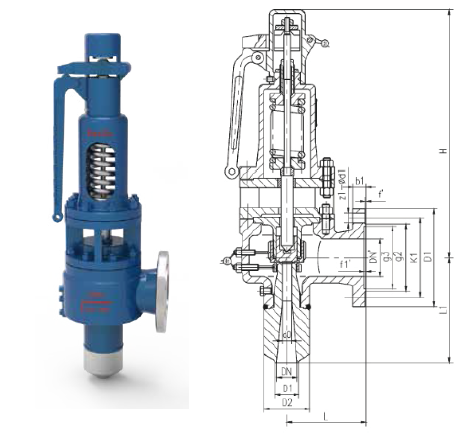

Structure briefing

1 .the main characteristics of the spring fully bore type safety valve are: simple structure, good seal performance, accurate opening pressure, large discharge capability, low differential reseating pressure and convenient adjustment, etc.

2.Nozzle seat: it is the Laware Nozzle type seat. The speed of the steam reaches the velocity of sound when passing the exit way of the seat; the sealed surface of the seat at is made of hard alloy of cobalt by overlaying welding. Large discharge coefficient, fine abilites of anti friction and corrosion resistance and long durability are recognzech.

3.Thermo elastic disc: the disc is of thermo dlastic sturcture. Taking the advantage of its mi nor out-of shape f eat-u re when under the medium pressure, the sial ability has been raised, and the problem that pre-discharge phenomenon of the safety valve happens when the medium pressure approaching the set pressure has been overcome. The sealed surface of thedisc has adopted the advanc id techology of laser heat hardening to increase thehardn ESS and the ability of anti-friction and corrosion sistance.

4.Upper adjusting ring: the valve can acquire appropriate reseating pressure by adjusting the upper adjusting ring to change the flow direc-tion of the medium discharged from the seat.

5.Lower adjusting ring: the valve can rapidly react full born the discharging process by adjusting the adjusting ring.

6.Back pressure adjusting sleeve: it is an auxiliary apparatus that serves to adjust the back pressure of the disc to acquire appropriate dif-ferential reseating pressure.

Installation instruction

1 .The safety valve shall be in stalled vertically a nd it would be better to in stall the valve directly upon the adaptor of the container or the pipe. The inside diameter of the adaptor shall be no less than that of the inlet pipeof the safety valve.

2.To avoid the thermal stress that is caused by thethermal expansion of the discharge pipe, the exit way of the safety valve shall be equipped with appropriate expansion joint. The inside diameter of the dis-charge pipe should larger than the diameter of the exit way of the valve. Its length shall be as short and possible and no bent is allowed. The weight of both the discharge pipe and the ex pa nsion joint hall not be applied to the safety valve, and they shall be fastened upon the con-struction. The distance between both centerlines of the discharge pipe and the valve body shall be as short as possible.

3.The exit way ofthe muffler shall have enough area, in order to avord producing back pressure that would affect the discharge capability of the valve.

4.Water drainage pipes shall be installed at the ends of both the exhaust pipe and the body; the exit of the back pressure adjusting sleeve shall be be equipped with short bend.

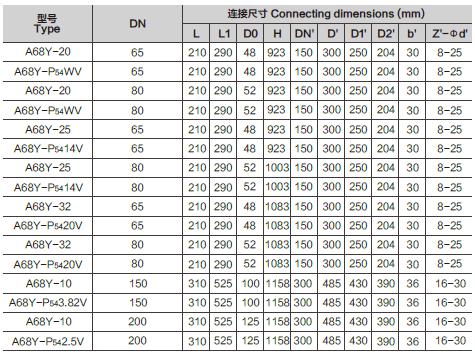

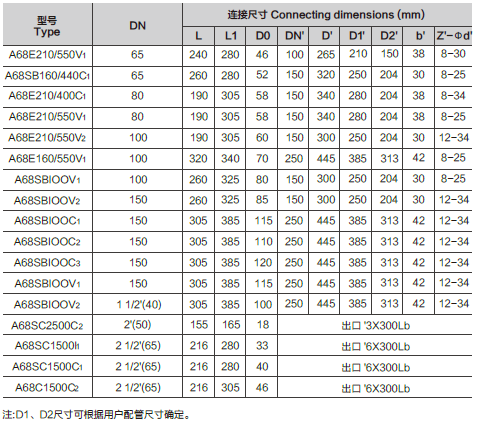

Main External Dimensions

Main External Dimensions

|

Previous:Dual-lever Safety Valve

Next:Main Safety Valve |

Back to list |

Add: South side of Tongfa Road, Quanshan District, Xuzhou City,Jiangsu Province,China

Tel: +86-516-85776002

Fax: +86-516-85773002

E-mail: sales@basco.cc

Mobile Website

Official WeChat