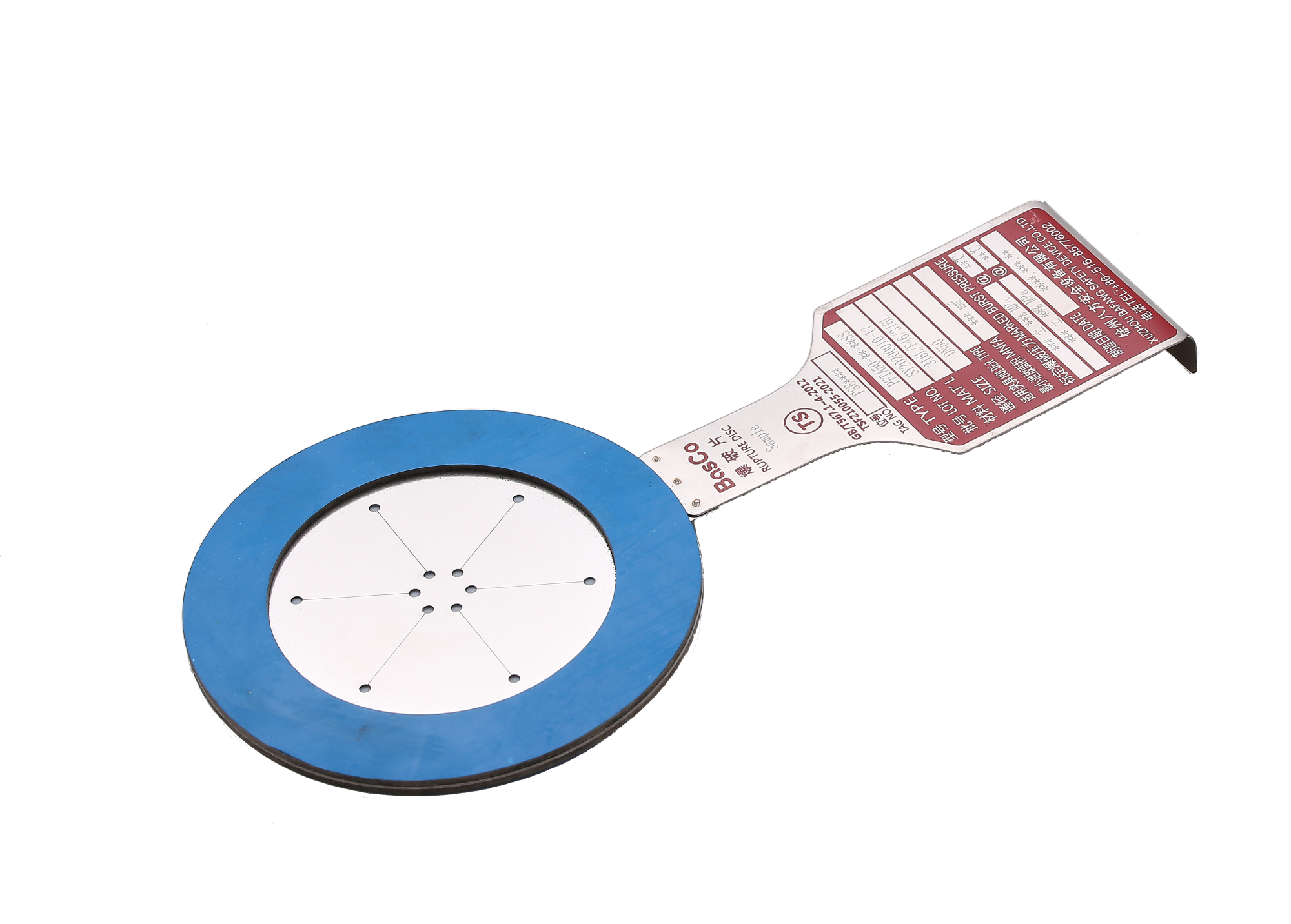

Flat composite rupture disc with gasket is evolved from LF rupture disc,mainly used in low pressure application. PF rupture disc can mount between flanges.

Note: Types and Specifications of Safety devices need to be calculated and selected according to the specific working conditions of the protected equipment and systems before quotations.

We offer 24/7 Emergency support. Contact our instant access emergency line for immediate problem resolution.

Tel: +86 516 8577 6002

WhatsApp: +86 13912009262

International Inquiries | E-mail: sales@basco.cc

Technical features:

• State-of-the-art laser slotted metal section

• No disc holder required. Mounts between standard or simple flanges

• Standard materials of construction: 316SS metal section(s), TFE seal, Non-asbestos gaskets (Other materials available)

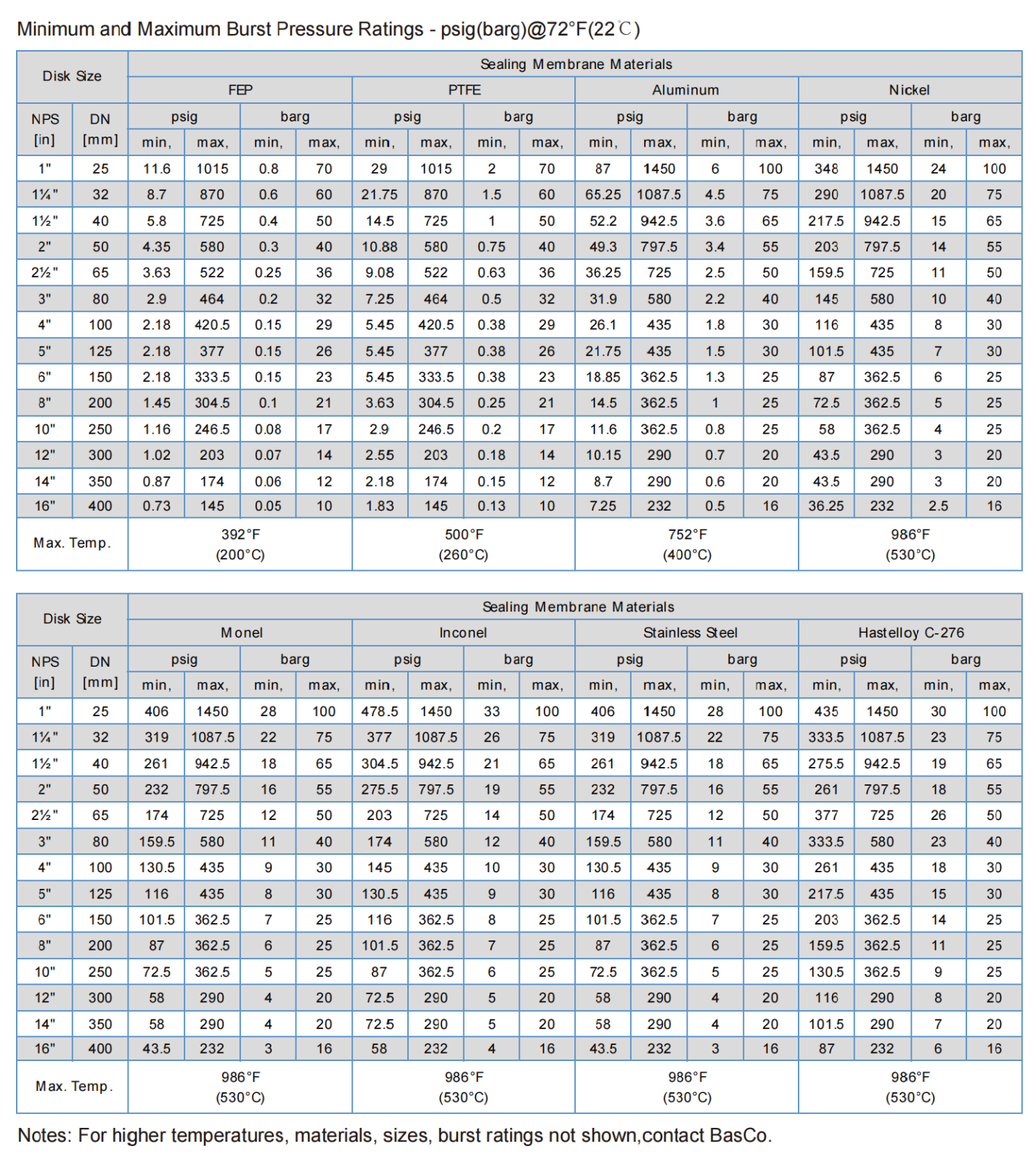

• Burst ratings from 0.02barg to100 barg

• Sizes from 25mm to 1200mm

• Operating ratios up to 50% of the low end of burst tolerance

Options:

• Burst Indication

• Teflon Gaskets

• Holder

• Railcar Disc

Storage Tank Protection

Storage Tank Protection Relief Valve Protection Storage tanks are made from relatively light gauge materials. This limits their ability to contain pressure and, if they are emptied without proper venting, makes them vulnerable to collapse.PF series rupture discs provide simple, inexpensive protection against either condition.

Disc size should be at least equal to the size of the flow inlet or outlet connection (whichever is greater) to the tank. Maximum rupture pressure should be no greater than the design pressure or vacuum (whichever is smaller) of the tank. Minimum rupture pressure should be at least 2 times the maximum working pressure or vacuum (whichever is greater) to which the tank will be exposed.

Relief Valve Protection

Corrosive elements in the atmosphere can enter a relief valve through its outlet and attack the valve's working parts. This may prevent the valve from functioning properly. Valves with outlets connected to common headers are especially vulnerable. A PF series rupture disc mounted on the valve's outlet flange protects valve components from hostile environments.

Disc size should be the same as the outlet flange of the valve. Maximum rupture pressure should be no greater than the set pressure of the valve. Minimum rupture pressure should be at least double the maximum working pressure in the header.